The European factory is preparing significantly more intelligent. Nvidia announcement on AI massive cloud cloud in Germany means that manufacturers in Europe will soon have access to energy equivalent to thousands of SuperCompters and help them design products faster, predict machine failures than they are, and optimize production in a way.

The NVIDIA Industrial AI Cloud Initiative has been unveiled in GTC Paris during Vivaty exceeds the traditional cloud computing by creating what Jensen Huang describes as a “AI” factory specifically designed for manufacturing applications.

Unlike AI, consumers’ services focusing on the infrastructure of complex compartment requirements of industrial processes, from the simulation of product design to factory underfloor operation in real time.

What does it differ from a regular cloud computing?

Traditional cloud services primary data storage and basic computing tasks. However, the industrial cloud AI nVidia is created for intensive mathematical calculation required in production.

Think about it as a difference between a standard office computer and a supercomputer designed for weather forecasts – both process information, but one is much stronger for specific tasks.

The device will include 10,000 GPUs, includes the latest DGX B200 NVIDIA systems and RTX Pro. To mention this in the perspective, the only modern GPU can perform calculations that would require thousands of traditional computer processors. Massive computing power allows manufacturers to operate complex simulations that previously lasted weeks in just hours or days.

Philosophy of “two factories”

The concept of Huang that “each manufacturer needs two factories: one for the production of things and the other to create intelligence that drives them” encapsulates the basic shift that occurs in modern production.

The physical factory produces the goods, while the digital factory – probably driven by AI nVidia cloud industrial AI – generates the needy to optimize production.

Digital twins help manufacturers test new production methods, predict equipment failure and optimize supplier chains in virtual real world changes.

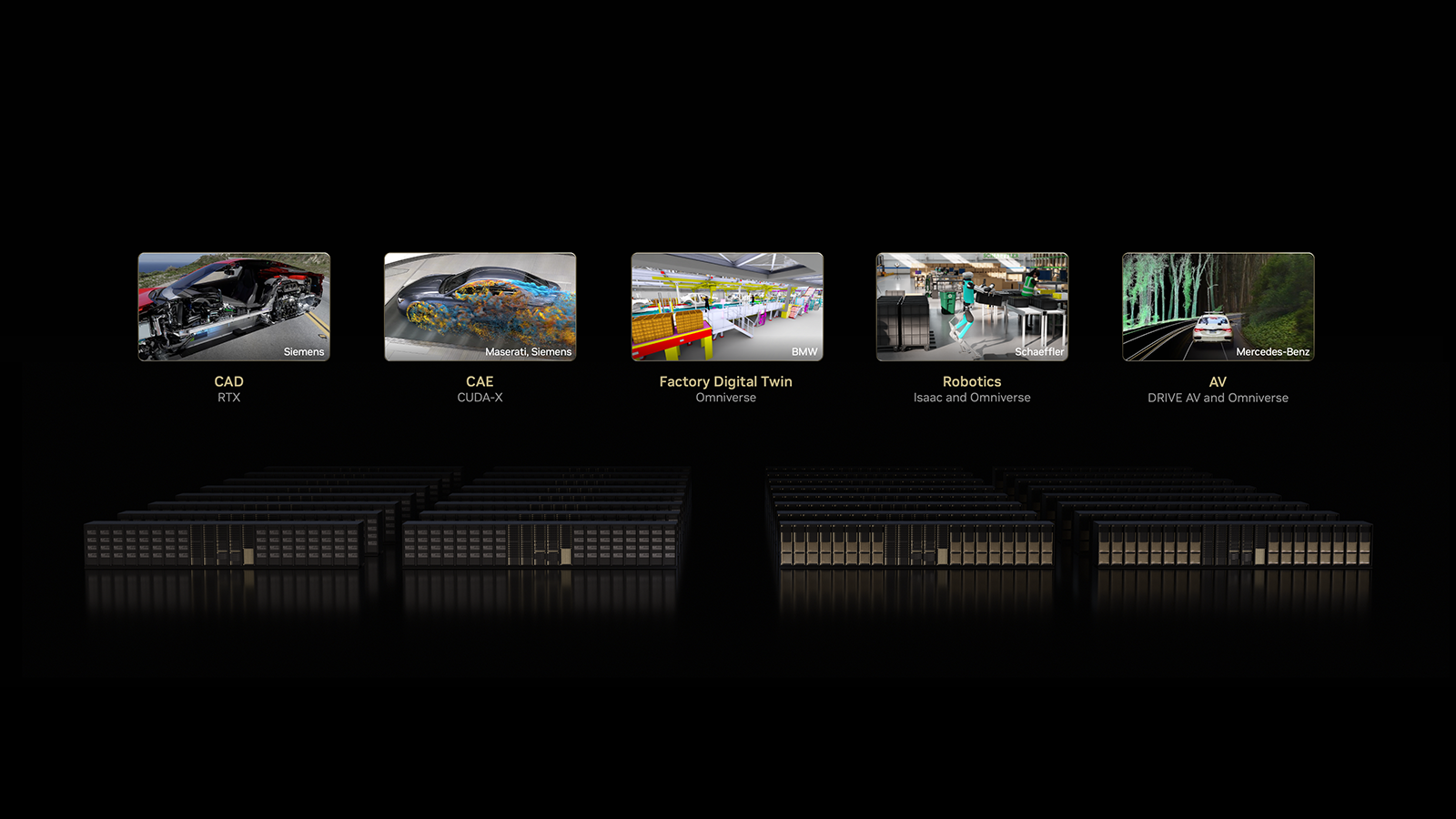

The BMW Group is an example of this approach, the Omnivers Platform to see to create digital twins of entire production devices, allowing global teams to work together to optimize the factory.

Applications in the real world are already in progress

The announcement is not only about future options – several European manufacturers are already using NVIDIA technology with impressive results. Volvo Cars reached 2.5x acceleration in fluid simulations for its EX90 electric vehicle using eight GPU NVIDIA Blackwell GPUs.

Similarly, Schaeffler implements AI-Powred automation in its 100+ production facilities using digital twins to support efficient and safe production. Mercedes-Benz employs Omnivers for designing and optimime factory assembly line practically, reducing downtime and improving the efficiency of its global operations.

Software ecosystem

Success of NVIDIA Industrial AI Cloud -dependent software partnerships with established industrial players. Siemens, Ansys and Cadence integrate AI nVidia technologies into existing software platforms and create an ecosystem for manufacturers.

Ansys is Omnivers Incorporation into its Fluid Simulatory Software, while Cadence announced its Millennium M2000 Supercombeter this software design with NVIDIA CUDA-X libraries. Partnership ensures that manufacturers can use well -known software interfaces.

Economic and strategic consequences

Investment signaling of the recognition of Europe Nvidia as a production center and represents a bet on industry digitization in the region. The device will serve as a counterbalance with similar investments in Asia and North America and potentially gives European manufacturers a competitive advantage in the production of A.

Timing is significant because European manufacturers face growing pressure to improve efficiency and competition with cheaper production areas. The NVIDIA Industrial AI cloud offers a way to maintain production competitiveness through technological superiority than a reduction in costs.

Challenges and Reflections

Despite the promising prospects, several challenges remain. The success of the initiative depends on the willingness of manufacturers in the necessary infrastructure and training for the use of resources.

Concentration of powerful computing sources of questions about data safety and technological dependence. European manufacturers will have to balance the benefits of AI shared infrastructure with concern about ownership and resistance to a supplier chain.

However, NVIDIA will build German facilities such as “Launchpad to accelerate AI’s development and adoption for European manufacturers in anticipation of AI gigafactors”. This suggests that the current investment is only the beginning of a wider investment in European production infrastructure.

(Photo: Nvidia)

See also: Taiwan builds AI SuperCompleut with Nvidia and Foxconn

Do you want to know more about cyber security and cloud from industry leaders? Check out Cyber Security & Cloud Expo in Amsterdam, California and London.

Explore other upcoming events and webinars with technology and webinars driven Techforge here.

(tagstotranslate) ai